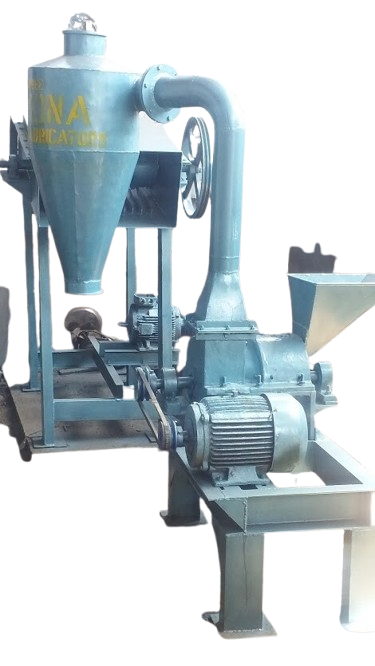

Impact pulverizer manufacturer in India we are leading manufacturer of MS impact pulverizer shree mona fabricators impact pulverizer meets most capacity requirements. It lends themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 B.S.S. Meshes depending to a considerable extent on the particular materials being handled. The techno wings impact pulverizer / pulveriser is a versatile grinding unit of heavy and rugged construction and built for continuous operation day after day. The impact pulverisers are especially designed for the medium fine, and fine size reduction. The impact pulverisers meet most capacity requirements and lend themselves to a wide degree of adjustments with fineness of the finished product ranging from about 60 mesh to bulk passing through 300 mesh, depending on a considerable extent to the particular material being handled. Unlike an ordinary hammer mill, it has no screens to break, wear out or clog in the crushing chamber. The techno wings impact pulverisers are combines grinding, classifying and conveying all in one single unit. Operating principle of impact pulverizer / pulveriser The impact pulverizer consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft. Raw material to be pulverized enters the crushing chamber through the hopper or the automatic rotary feeder. The impact of the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the oversize particles are rejected by the classifier and returned to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust less operation and for no loss of ground powder. Typical application of impact pulverizer / pulveriser The techno wings impact pulverizers are used for a wide range of application e.g. Agricultural, chemicals, carbon and graphite, coal, coke, coconut shell and wood saw dust, clay, dye stuff and pigments, detergents, ferro-alloys fertilizers, fillers, food products, herbs and spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, et cetera Outstanding features of impact pulverizer / pulveriser High speed rotor assembly two-way reversible hammers / beater Easy access to impact pulverizers interior through dual access doors Available in different size and models Cold and silent running Dust free operations Robust construction Low specific power consumption Durable long life Guaranteed grinding efficiency, particle sizes are finer and more uniform than that obtained from machine using screen Construction of impact pulverizer / pulveriser Type: Air swept impact mill with whizzer classifier operation in closed circuit Body: solid iron, machined and aligned on a strong iron base with top covers bolted. Feeder: Automatic rotary feeder, gear driven from the main shaft with feed control mechanism crushing chamber: Lined with renewable solid iron ( stainless steel optional) breaker plates Rotor: machined mild steel thick plates mounted on main shaft: solid alloy steel Classifier: mild steel whizzier classifier with adjustable spider to control fineness of ground powder up to 300 mesh depending on the type of material being pulverized Bearings: self-aligning ball bearings in cast iron housing with suitable grease cups for lubrication Hammers: forged alloy steel, hard faced, with manganese steel electrodes and balanced. Blower: paddle type with replaceable blades Cyclone: mild steel sheet fabricated dust collector: top and bottom halves of mild steel sheet, to be interconnected by dust bags Piping: all interconnecting mild steel piping supplied with loose flanges to facilitate easy erection Standard accessories of impact pulverizer / pulveriser Motor pulley Cotton balloons. Anti vibrating foundation stand with adjustable rail for motor Extra accessories of impact pulverizer / pulveriser Suitable totally enclosed fan cooled three phase sq. cage motor as per is: 325. {electricity (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz, 1/3 phase} Starters, main switch, ampere meter, capacitor for three phases Foundation bolts V belts All contacting parts stainless steel 304 / 316 can be accommodated |impact pulverizer machine manufacturer in vadodara , gujrat , india| |impact pulverizer machine manufacturer in Kolkata, West Bengal| |impact pulverizer machine manufacturer in Jaipur, Rajasthan| |impact pulverizer machine manufacturer in Mumbai, Maharashtra| |impact pulverizer machine manufacturer in Kerala| |impact pulverizer machine manufacturer in karnataka|

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Impact pulverizer manufacturer in India we are ...

2024-09-19T02:21:00

Impact pulverizer manufacturer in India we are leading manufacturer of MS impact pulverizer shree mona fabricators impact pulverizer meets most capacity requirements. It lends themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 B.S.S. Meshes depending to a considerable extent on the particular materials being handled. The techno wings impact pulverizer / pulveriser is a versatile grinding unit of heavy and rugged construction and built for continuous operation day after day. The impact pulverisers are especially designed for the medium fine, and fine size reduction. The impact pulverisers meet most capacity requirements and lend themselves to a wide degree of adjustments with fineness of the finished product ranging from about 60 mesh to bulk passing through 300 mesh, depending on a considerable extent to the particular material being handled. Unlike an ordinary hammer mill, it has no screens to break, wear out or clog in the crushing chamber. The techno wings impact pulverisers are combines grinding, classifying and conveying all in one single unit. Operating principle of impact pulverizer / pulveriser The impact pulverizer consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft. Raw material to be pulverized enters the crushing chamber through the hopper or the automatic rotary feeder. The impact of the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the oversize particles are rejected by the classifier and returned to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust less operation and for no loss of ground powder. Typical application of impact pulverizer / pulveriser The techno wings impact pulverizers are used for a wide range of application e.g. Agricultural, chemicals, carbon and graphite, coal, coke, coconut shell and wood saw dust, clay, dye stuff and pigments, detergents, ferro-alloys fertilizers, fillers, food products, herbs and spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, et cetera Outstanding features of impact pulverizer / pulveriser High speed rotor assembly two-way reversible hammers / beater Easy access to impact pulverizers interior through dual access doors Available in different size and models Cold and silent running Dust free operations Robust construction Low specific power consumption Durable long life Guaranteed grinding efficiency, particle sizes are finer and more uniform than that obtained from machine using screen Construction of impact pulverizer / pulveriser Type: Air swept impact mill with whizzer classifier operation in closed circuit Body: solid iron, machined and aligned on a strong iron base with top covers bolted. Feeder: Automatic rotary feeder, gear driven from the main shaft with feed control mechanism crushing chamber: Lined with renewable solid iron ( stainless steel optional) breaker plates Rotor: machined mild steel thick plates mounted on main shaft: solid alloy steel Classifier: mild steel whizzier classifier with adjustable spider to control fineness of ground powder up to 300 mesh depending on the type of material being pulverized Bearings: self-aligning ball bearings in cast iron housing with suitable grease cups for lubrication Hammers: forged alloy steel, hard faced, with manganese steel electrodes and balanced. Blower: paddle type with replaceable blades Cyclone: mild steel sheet fabricated dust collector: top and bottom halves of mild steel sheet, to be interconnected by dust bags Piping: all interconnecting mild steel piping supplied with loose flanges to facilitate easy erection Standard accessories of impact pulverizer / pulveriser Motor pulley Cotton balloons. Anti vibrating foundation stand with adjustable rail for motor Extra accessories of impact pulverizer / pulveriser Suitable totally enclosed fan cooled three phase sq. cage motor as per is: 325. {electricity (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz, 1/3 phase} Starters, main switch, ampere meter, capacitor for three phases Foundation bolts V belts All contacting parts stainless steel 304 / 316 can be accommodated |impact pulverizer machine manufacturer in vadodara , gujrat , india| |impact pulverizer machine manufacturer in Kolkata, West Bengal| |impact pulverizer machine manufacturer in Jaipur, Rajasthan| |impact pulverizer machine manufacturer in Mumbai, Maharashtra| |impact pulverizer machine manufacturer in Kerala| |impact pulverizer machine manufacturer in karnataka|

2024-09-19T02:21:00

Keywords

- 60 mesh

- V belts

- 300 mesh

- 50/60 Hz

- dye stuff

- 1/3 phase

- top covers

- main shaft

- wide range

- cage motor

- paddle type

- West Bengal

- main switch

- wide degree

- fine powder

- medium fine

- solid shaft

- Easy access

- impact mill

- Raw material

- ampere meter

- marine feeds

- three phases

- liner plates

- loose flanges

- bottom halves

- food products

- coconut shell

- ground powder

- swing hammers

- special power

- feed material

- particle sizes

- silent running

- dust collector

- different size

- three phase sq

- pulveriser Type

- ground material

- adjustable rail

- stainless steel

- one single unit

- dust bags Piping

- strong iron base

- mild steel sheet

- adjustable spider

- finished products

- dual access doors

- cast iron housing

- mild steel piping

- 300 B.S.S. Meshes

- replaceable blades

- oversize particles

- impact pulverisers

- fineness regulation

- Typical application

- grinding efficiency

- classified material

- lubrication Hammers

- screen Construction

- Robust construction

- Operating principle

- rugged construction

- considerable extent

- fine size reduction

- dust less operation

- closed circuit Body

- Outstanding features

- particular materials

- continuous operation

- leading manufacturer

- Dust free operations

- renewable solid iron

- ordinary hammer mill

- breaker plates Rotor

- suitable grease cups

- versatile grinding unit

- automatic rotary feeder

- motor Extra accessories

- mild steel thick plates

- ferro-alloys fertilizers

- pressure gradient creator

- High speed rotor assembly

- two-way reversible hammers

- manganese steel electrodes

- most capacity requirements

- self-aligning ball bearings

- whizzer classifier operation

- solid alloy steel Classifier

- Impact pulverizer manufacturer

- mild steel whizzier classifier

- Low specific power consumption

- techno wings impact pulverizers

- Anti vibrating foundation stand

- easy erection Standard accessories

- impact pulverizer machine manufacturer

- feed control mechanism crushing chamber

- pulveriser Motor pulley Cotton balloons

- MS impact pulverizer shree mona fabricators impact pulverizer

Submit Your Enquiry